Flex vs. Rigid-Flex PCBs

As circuitry becomes denser and devices smaller, the question isn’t just what goes on the board, it’s what the board must do. Flex and rigid-flex PCBs address that challenge from two directions, one through adaptability, the other through integrated strength. The choice between them enforces how electrical performance, mechanical behavior, and reliability intersect within a specific design environment. Understanding their differences helps engineers and OEM teams make decisions that extend product life, improve manufacturability, and protect performance from prototype through production.

Understanding Flexible PCBs

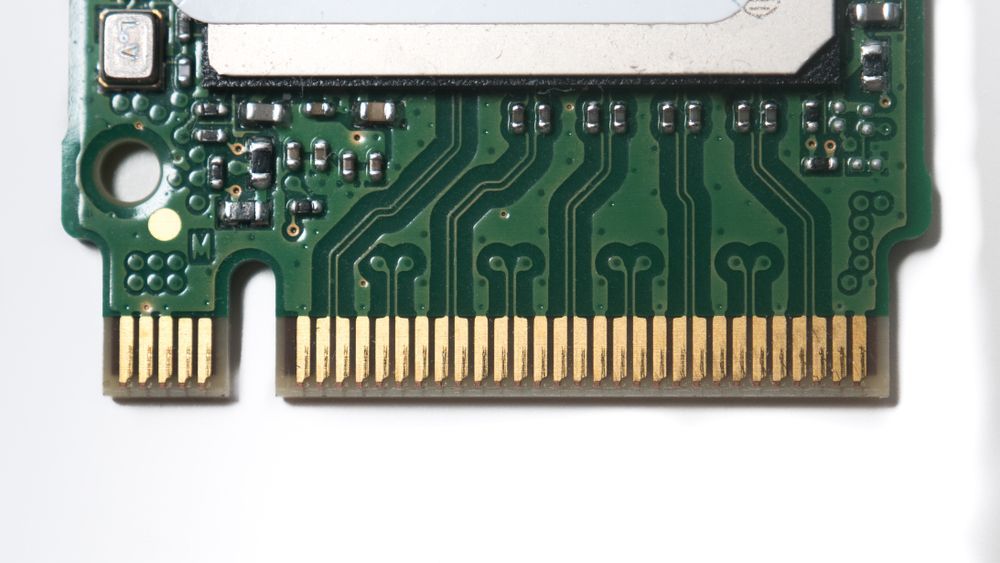

What Is a Flexible PCB?

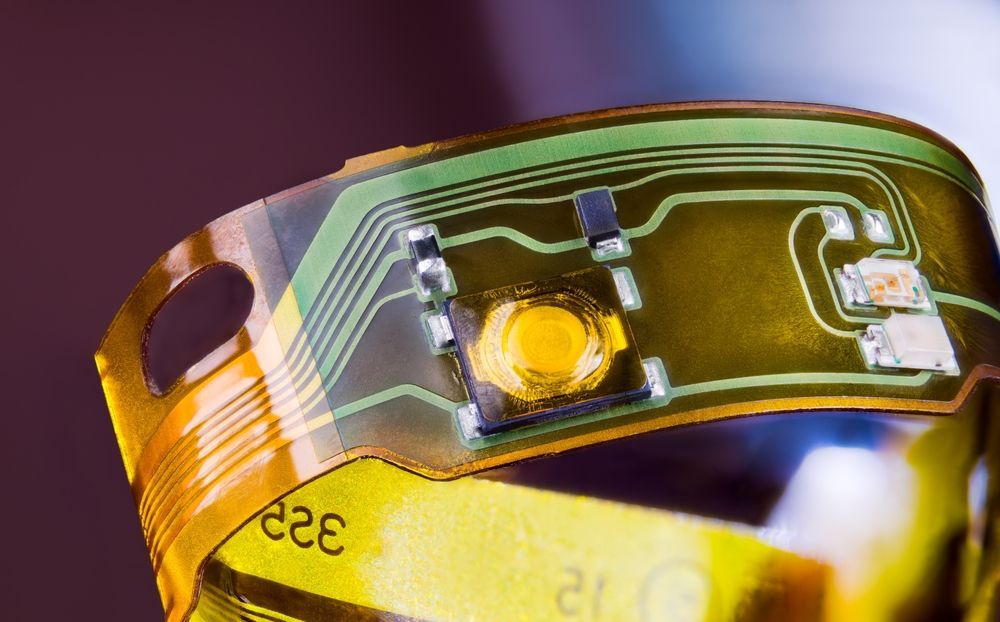

A flexible printed circuit board uses a thin, bendable substrate (most often polyimide) to create an interconnect that can flex, fold, or wrap within tight mechanical spaces. Copper conductors are etched onto the flexible film and protected by coverlays or coatings that maintain insulation while allowing movement. Flex PCBs eliminate the need for many connectors and cables, streamlining the electrical pathway and reducing potential failure points.

Manufacturing Process for Flex Circuits

The process begins with copper-clad polyimide laminated using adhesive or adhesive-less systems, depending on performance requirements. Circuits are patterned by photolithography and etched with precision to maintain trace geometry through potential bend zones. Coverlays or flexible solder masks are added for insulation and protection. The boards are then drilled or laser cut, plated, and finished (often with ENIG or immersion tin) to ensure robust conductivity at interfaces. Every step requires strict control of tension, temperature, and material alignment to maintain flexibility without distortion.

Benefits of Flexible PCBs

- Space efficiency: Allows three-dimensional folding or wrapping to fit compact enclosures.

- Reduced interconnects: Fewer cables and connectors mean fewer mechanical stress points.

- Weight savings: Ideal for applications where every gram matters.

- Vibration tolerance: Flexible substrates absorb and distribute mechanical stress.

- Simplified assembly: Components can be pre-mounted or interconnected before folding into the final form.

These attributes make flex PCBs an

effective solution for designs that require movement, a lightweight structure, or routing through constrained geometries.

Challenges and Limitations

Flex circuits require careful handling and tight process control. The thin substrates can crease, tear, or delaminate if overstressed, and design tolerances are narrower than with rigid boards. Material and fabrication costs are typically higher per square inch, though overall system costs often drop when connectors and cabling are eliminated. In complex builds, bend radius and layer count become key constraints that must be defined early in design.

Common Applications for Flexible PCBs

Flexible boards are widely used in medical wearables, imaging probes, consumer devices, cameras, and compact sensors. They’re also common in aerospace instrumentation and automotive electronics, where lightweight, dynamic connections improve reliability and reduce harness complexity.

What Is a Rigid-Flex PCB?

Rigid-flex printed circuit boards merge the stability of rigid substrates with the adaptability of flexible circuitry. Rather than relying on connectors or cables between separate boards, rigid-flex designs integrate both structures into a single, continuous assembly. The flexible layers carry signals through or between rigid sections, allowing movement while maintaining electrical continuity. This configuration supports complex, compact systems that require both durability and efficient signal routing.

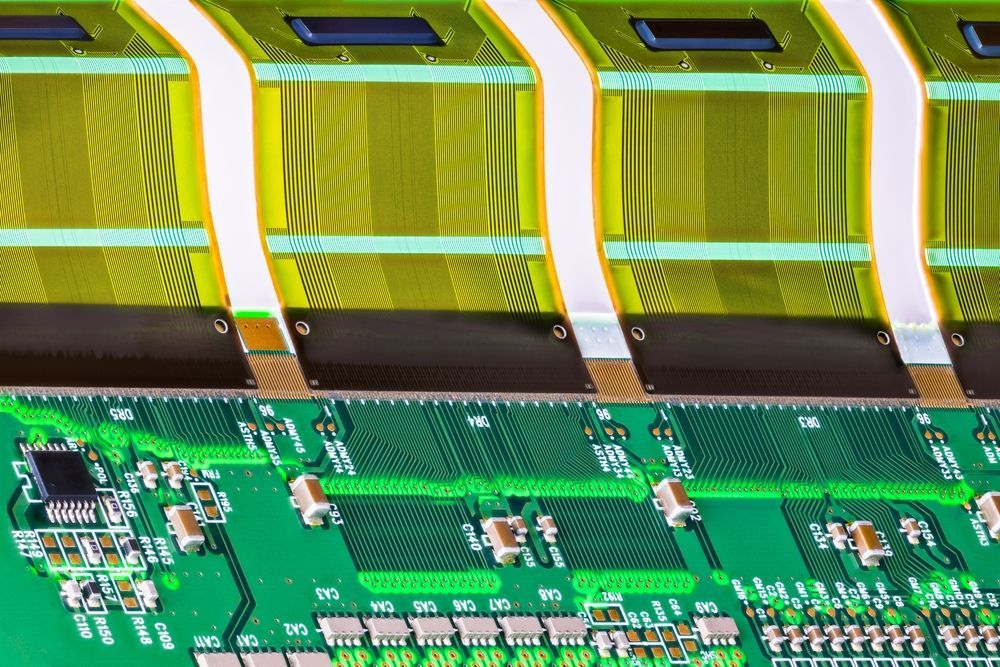

Rigid-Flex PCB Construction

A typical rigid-flex stackup consists of rigid FR-4 or equivalent cores bonded to flexible polyimide layers. The flex layers are laminated between rigid zones or extended outward to create bendable interconnects. Vias can pass through rigid sections or terminate within flex layers, depending on design intent. Controlled impedance traces and balanced copper distribution are essential to prevent warping during lamination. Stiffeners or mechanical supports are often added in component-dense areas to preserve planarity and solder joint integrity.

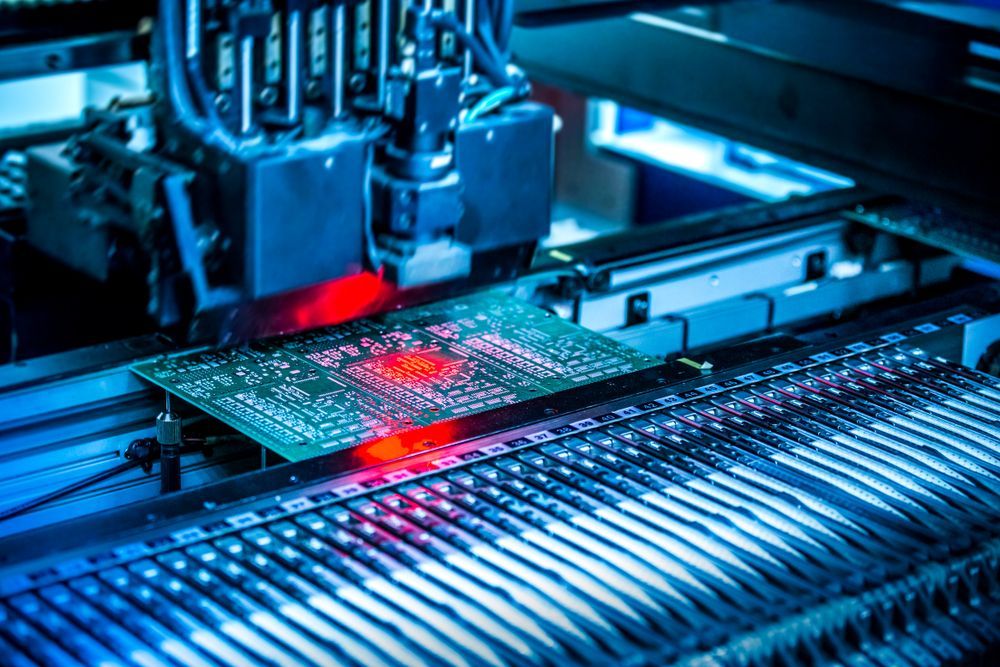

The Rigid-Flex Manufacturing Process

Rigid-flex fabrication combines multiple sequential lamination steps. Each stage involves precise alignment of flexible and rigid sections, laser drilling for vias, and copper plating to maintain connectivity through the stack. Because heat and pressure affect different materials in distinct ways, process control is critical. Once laminated, the board is routed or laser-cut to define flexible regions and component outlines. Surface finishes, typically ENIG or electroplated hard gold, are applied last to protect exposed copper and ensure long-term contact reliability.

Key Advantages of Rigid-Flex Designs

Rigid-flex technology minimizes interconnects and simplifies assembly, resulting in fewer solder joints and improved electrical performance. Replacing connectors and wiring harnesses with integrated layers reduces weight and potential points of failure. The rigid zones provide stable mounting surfaces for components, while the flexible interconnects accommodate motion, vibration, or dimensional constraints. The result is a clean, high-density structure that enhances signal integrity and mechanical strength.

Challenges and Limitations

Rigid-flex designs require more upfront planning and precision than traditional rigid or flex-only boards. The hybrid stackup increases fabrication complexity and cost, especially for low-volume builds. Tooling, lamination sequencing, and impedance modeling add engineering overhead. Because rework can be difficult once assembled, early collaboration between design and manufacturing is essential to achieving stable yields and long-term reliability.

Common Applications for Rigid-Flex PCBs

Rigid-flex assemblies are found in aerospace avionics, defense guidance systems, medical imaging equipment, robotics, and industrial automation. They perform well in environments where vibration, limited space, and continuous operation demand both mechanical resilience and electrical integrity. Many next-generation systems rely on rigid-flex boards to combine compact form factors with extended operational life.

Flexible vs. Rigid-Flex PCBs: A Comparative Analysis

Choosing between flexible and rigid-flex PCB designs begins with understanding how each performs under real-world demands. Both offer solutions for space, movement, and reliability, yet they differ in structure, manufacturing approach, and long-term behavior. Aligning the right technology with the application ensures dependable operation and efficient production.

Performance and Reliability

Flexible circuits excel in designs that require continuous motion or tight folding, maintaining signal integrity through repetitive bending cycles. Their ability to absorb vibration and mechanical strain makes them ideal for portable and wearable devices. However, they rely on external support structures or enclosures for stability.

Rigid-flex boards, by contrast, are self-supporting. The rigid sections anchor components, while flexible layers bridge moving or spatially constrained areas. This configuration improves vibration tolerance and reduces connection failures by eliminating external connectors. Over time, rigid-flex assemblies tend to demonstrate greater durability and electrical consistency in high-stress environments.

Design Considerations

Flex designs favor simplicity. Think thin layers, broad bend zones, and lightweight routing. However, their mechanical strength depends on proper bend radius and copper balancing. Rigid-flex boards introduce more variables: controlled impedance traces, stiffeners, and transitions between rigid and flexible areas must all be planned in detail. Successful rigid-flex design begins early, integrating electrical, mechanical, and manufacturing perspectives to prevent delamination, cracked copper, or misalignment during lamination.

Cost Implications

At first glance, flexible PCBs appear less expensive due to their lower material volume. Yet when connectors, cables, and assembly steps are considered, system-level cost savings often narrow the gap. Rigid-flex designs carry higher tooling and fabrication costs upfront, but they can reduce total assembly time, improve reliability, and lower lifecycle maintenance. For applications requiring sustained performance under demanding conditions, the higher initial investment of rigid-flex often results in measurable long-term value.

EI Microcircuits: Delivering Rigid-Flex PCB Solutions

Reliable performance in a rigid-flex design begins long before the first board is built. It starts with engineering alignment. This means translating mechanical intent, material constraints, and electrical goals into a manufacturable design. At EI Microcircuits, we bring that alignment to every project by combining early-stage collaboration with disciplined process control. Our teams handle complex hybrid stackups daily, managing the transition from flexible to rigid materials with precision that protects both electrical and mechanical integrity.

Design for Manufacturability (DFM) Support

We engage at the design phase to review stackup structures, bend zones, and copper balancing before production begins. Our engineers verify that each transition point between rigid and flexible layers meets IPC and customer-specific requirements. By addressing layout and material selections early, we reduce design risk, improve yield, and eliminate downstream rework. This approach also supports controlled impedance planning for signal-critical paths, which is a key consideration in high-speed and high-reliability systems.

Precision Assembly and Testing

Our rigid-flex assembly lines operate under tightly managed parameters for temperature, alignment, and adhesive control. Automated Optical Inspection (AOI), X-ray imaging, and functional testing confirm that internal vias, copper paths, and plated edges meet strict design tolerances. Each assembly undergoes electrical continuity and insulation resistance testing to validate performance before final integration. This attention to process detail ensures that every build meets the mechanical endurance and signal integrity expected in regulated

industries.

Turnkey Integration and Lifecycle Support

At EI Microcircuits, we provide full lifecycle manufacturing to extend beyond assembly and include box-build integration, cable and harness routing, and final functional testing. All operations are performed within quality management systems certified to ISO 13485 and AS9100D, ensuring compliance, traceability, and documentation from prototype through sustained production. Our support model is built for long-term partnerships, enabling OEMs to consolidate complex builds with a single trusted source.

Choosing the Right PCB for Your Application

Selecting between flexible and rigid-flex circuit designs often comes down to understanding how the board will live and work inside its environment. Each design type offers a different balance of movement, structure, and integration, and the best choice depends on where reliability, size, and performance intersect.

A flexible PCB is well-suited when motion, lightweight design, or space constraints define the challenge. These boards adapt to enclosures that move or fold, simplify wiring, and allow designers to create compact systems without sacrificing connectivity. They perform best in portable devices, wearable sensors, and assemblies where the board itself must bend or conform to the product’s shape.

A rigid-flex PCB fits when electrical precision must coexist with mechanical strength. It replaces connectors and cables between rigid sections, improving durability while maintaining flexibility where needed. Rigid-flex builds also streamline installation by integrating multiple circuit layers into one unified assembly. This approach is ideal for products that experience vibration, frequent maintenance, or limited access, like aerospace controls, medical imaging systems, and automated industrial equipment.

In practice, the right decision often emerges through collaboration. Reviewing function, geometry, and reliability expectations with a manufacturing partner early helps ensure that the selected technology supports long-term performance and regulatory compliance.

Expect Solutions with EI Microcircuits

Every design tells a story of tradeoffs between space and structure, precision and flexibility, performance and manufacturability. Engineers live in that balance, shaping systems that must perform dependably in the field, not just on paper. At EI Microcircuits, our role is to guide that process from concept through production with the systems, experience, and discipline that turn design intent into measurable reliability.

We approach each build as an extension of our customer’s engineering team, combining advanced manufacturing capability with practical insight. Our facilities operate under quality management systems that include ISO 13485 and AS9100D, ensuring every assembly meets the performance and documentation standards required in medical, aerospace, defense, and industrial markets. That foundation, which is supported by automation, inspection, and experienced technical teams, keeps each project aligned with its purpose.

Push the limits of what your design can do.

Partner with EI Microcircuits to turn complex designs into flawless, field-ready systems. From flexible prototypes to mission-grade rigid-flex assemblies, we deliver precision, reliability, and results that speak for themselves.

let's talk

EI Microcircuits is comprised of three production facilities totaling over 100,000 square feet of climate-controlled manufacturing, engineering and warehousing. We are ready to be the solution to your next project. Contact Us, Request a Quote or Schedule a Tour today!

Manufacturing plant 1

1651 Pohl Road

Mankato, MN 56001

P: 507.345.5786

Manufacturing plant 2

2011 Klein Street

St. Peter, MN 56082

P: 507.934.5722

manufacturing plant 3

69 Power Drive

Mankato, MN 56001

P: 507.386.9160

*Each facility is configured to support your production needs. While maintaining continuity with each other in equipment, training and process control, each facility offers its own specialty. All facilities share the same data center to allow for seamless manufacturing between locations.