How Are PCBs Made? End-to-End Solutions Explained

Every reliable product begins as a reliable circuit. From medical devices and avionics systems to industrial controls, printed circuit boards form the foundation for every electronic function. Yet building them well takes more than a line of solder or a list of parts. It takes coordination between design, manufacturing, and quality systems at every stage.

Step 1: Design and DFM Collaboration

Every successful build starts with design-for-manufacturability (DFM). Engineers and manufacturers work together to align the product’s electrical intent with its physical reality. At this stage, trace widths, layer counts, copper weights, and controlled impedance are defined alongside mechanical constraints.

A strong DFM review evaluates:

- Material selection and stackup configuration

- Component spacing, orientation, and solder joint accessibility

- Thermal management and power distribution

- Assembly sequence and test strategy

When you address manufacturability early, teams reduce risk, improve yield, and shorten development cycles. At EI Microcircuits, this collaboration forms the cornerstone of our process. Which transforms design intent into repeatable, reliable outcomes.

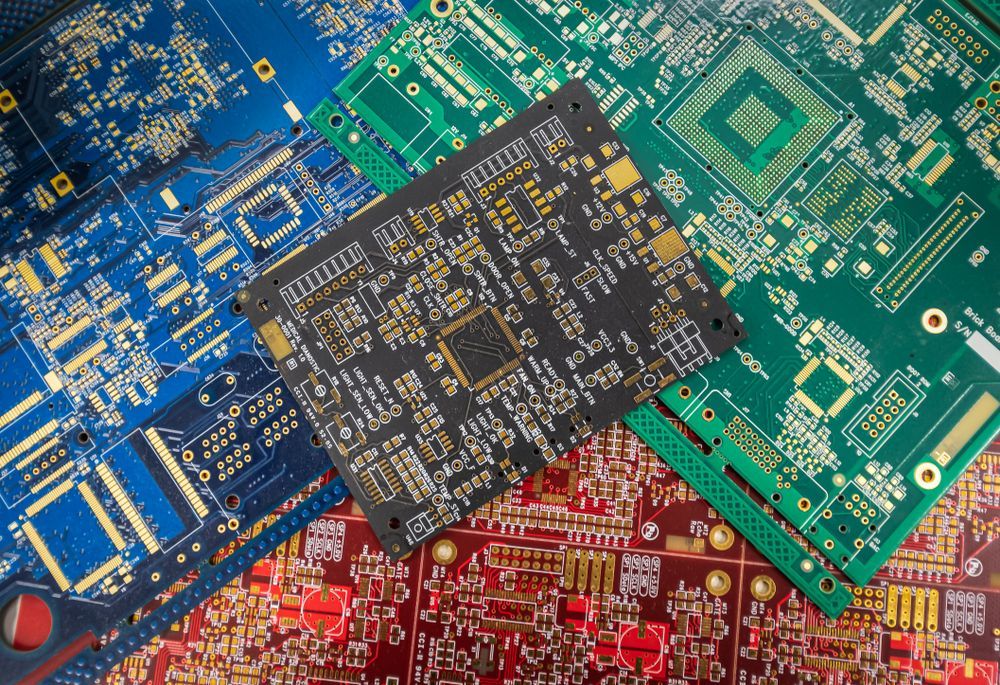

Step 2: PCB Fabrication

Fabrication converts the approved design into a physical board. Copper-clad laminates are cleaned, imaged, and etched to form conductive patterns across layers. Through-holes or vias are drilled and plated, creating electrical connections between layers.

Critical steps include:

- Inner layer processing for circuit imaging and etching

- Lamination under heat and pressure to bond multilayer stacks

- Drilling and plating to establish interconnect pathways

- Solder mask and surface finish application for protection and solderability

Surface finishes, like ENIG, immersion tin, or hard gold, are applied depending on the assembly’s environmental and functional requirements. Precision in this stage ensures dimensional accuracy, flatness, and adhesion for later assembly steps.

Step 3: Component Procurement and Material Traceability

Reliable builds depend on traceable materials. All components and substrates must originate from verified suppliers and carry the certifications needed for

regulated industries. EI Microcircuits maintains complete lot-to-lot material traceability. This helps ensure compliance with ISO 13485, AS9100D, and ITAR requirements.

Procurement teams validate:

- Component authenticity and RoHS/REACH compliance

- Proper storage and handling for moisture-sensitive devices

- Supplier performance history and quality records

This traceable supply chain supports long-term repeatability and product stewardship, which are key factors for aerospace, defense, and medical OEMs that require documented control at every stage.

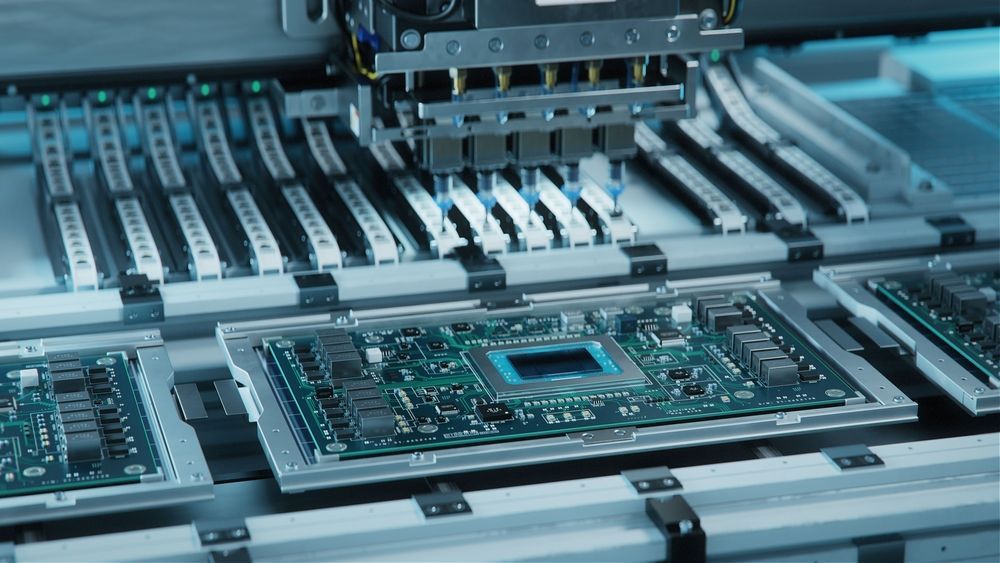

Step 4: PCB Assembly

Assembly transforms bare boards into functional circuits through either surface mount (SMT) or through-hole (THT) processes, or a hybrid of both.

- SMT Assembly uses automated pick-and-place machines to position components on solder-pasted pads before reflow soldering. This method supports high-speed, high-density designs.

- Through-Hole Assembly involves inserting components into drilled holes and soldering from the reverse side, offering mechanical strength for connectors and power parts.

Advanced inspection systems monitor alignment and solder integrity throughout the process. At EI Microcircuits, multiple technologies, such as reflow, selective solder, and wave soldering, operate in controlled environments to ensure consistency across every board and every build.

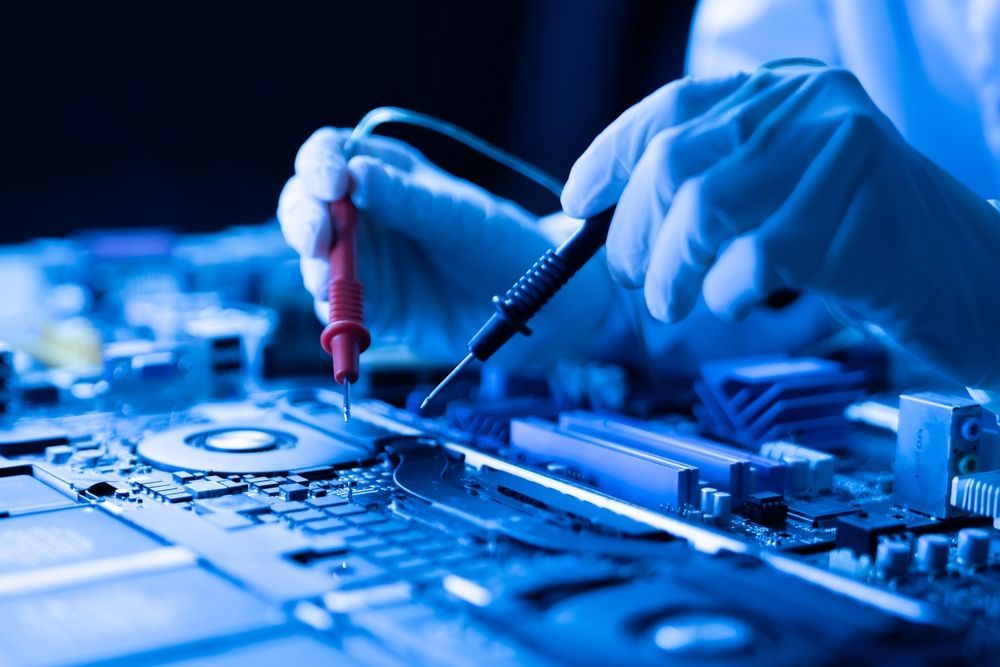

Step 5: Inspection and Test Processes

Testing validates what fabrication and assembly cannot always prove visually: that every connection performs as designed.

EI Microcircuits employs a full suite of verification methods, including:

- Automated Optical Inspection (AOI) for solder joint and polarity validation

- X-ray inspection for hidden leads such as BGAs and QFNs

- In-circuit and flying probe testing for electrical integrity

- Functional testing to confirm performance under real-world conditions

These processes create a closed-loop feedback system, capturing and correcting issues before they reach final assembly. And creates an integrated safeguard that ensures each product meets its intended specification.

Integrations that Enhance Performance and Reliability

Beyond component placement, modern electronics depend on mechanical, environmental, and electrical protection. EI Microcircuits extends manufacturing beyond the board itself to include specialized processes that strengthen and protect each assembly.

Conformal Coating and Overmolding

Protective coatings shield sensitive circuits from moisture, dust, and chemical exposure. Silicone, urethane, or acrylic coatings are precisely applied and cured to meet product-specific standards. Overmolding adds another layer of durability, encapsulating assemblies for vibration or environmental resistance in harsh conditions.

Box-Build and Full Turnkey Assembly

Complete product integration, including enclosure assembly, interface cabling, and final functional test, is managed under the same quality framework as the PCBA itself. Turnkey builds streamlined logistics and provides OEMs with a single point of accountability from the board through the final product.

Final Steps: Packaging, Warehousing, and Logistics

Once assemblies are verified, attention shifts to preservation and delivery. Packaging follows controlled procedures for electrostatic discharge (ESD) protection, moisture sensitivity, and mechanical safety. Each unit is labeled, serialized, and recorded in EI’s traceability system.

For long-term programs, assemblies can be stored in controlled warehousing environments, ensuring parts remain compliant and ready for deployment. Logistics support extends through documentation, serialization tracking, and coordination with customer production schedules.

EI Micro Builds for Regulated and Mission-Critical Markets

EI Microcircuits operates within the most demanding regulatory frameworks, supporting medical, aerospace, defense, and industrial automation markets. Our quality management systems (ISO 13485, AS9100D, and ITAR) govern every stage of production, from supplier qualification to final release. This ensures not only compliance, but consistency, accountability, and confidence across the full product lifecycle.

Every process, material, and verification step is designed to maintain performance in environments where failure is not acceptable.

Expect Solutions at Every Stage

Every engineer knows what’s at stake when a circuit fails. Even small issues can cascade into delays, recalls, or lost trust. And in industries where performance defines reputation, there’s no room for uncertainty.

That’s the pressure that defines this work. And it’s the same reason EI Microcircuits exists: to help teams rise above those risks with process, precision, and partnership.

We know what it takes to move a design from concept to production without compromise. We proudly prioritize clear communication, disciplined quality systems, and the technical foresight to anticipate problems before they appear. Our engineers work alongside yours to review stackups, validate materials, and confirm manufacturability. Our production teams ensure every board, connector, and assembly performs exactly as intended.

Reach out and partner with EI Microcircuits today, and bring your next PCB from design through delivery with precision, traceability, and reliability built in. You design the vision. We’ll make it real.

let's talk

EI Microcircuits is comprised of three production facilities totaling over 100,000 square feet of climate-controlled manufacturing, engineering and warehousing. We are ready to be the solution to your next project. Contact Us, Request a Quote or Schedule a Tour today!

Manufacturing plant 1

1651 Pohl Road

Mankato, MN 56001

P: 507.345.5786

Manufacturing plant 2

2011 Klein Street

St. Peter, MN 56082

P: 507.934.5722

manufacturing plant 3

69 Power Drive

Mankato, MN 56001

P: 507.386.9160

*Each facility is configured to support your production needs. While maintaining continuity with each other in equipment, training and process control, each facility offers its own specialty. All facilities share the same data center to allow for seamless manufacturing between locations.