RoHS Compliance in High-Reliability PCBA

In high-reliability sectors such as medical, aerospace, and defense, compliance with environmental regulations is as important as meeting performance standards. Restriction of Hazardous Substances (RoHS requirements) compliance limits the use of specific hazardous materials in electronic assemblies, reducing environmental impact while safeguarding human health.

For PCB assembly manufacturers, achieving RoHS compliance requires precise control of materials, processes, and documentation. These measures protect both the operational integrity of the product and the reputation of the OEM in regulated markets, providing

solutions that balance environmental responsibility with high performance.

What is RoHS Compliance?

RoHS, or Restriction of Hazardous Substances, is a European Union directive that limits the concentration of specific hazardous materials in electrical and electronic equipment. The primary restricted substances include lead, mercury, cadmium, hexavalent chromium, and certain flame retardants. Compliance helps reduce environmental contamination and health risks during manufacturing, use, and disposal of electronics.

Core Requirements of RoHS

To be RoHS compliant, a PCB assembly must contain each restricted material at levels below the defined maximum concentration values. Manufacturers must source components and materials that meet these limits, maintain documentation to verify compliance, and implement process controls that prevent contamination. Testing methods such as X-ray fluorescence (XRF) are often used to confirm material composition, particularly for high-reliability applications where consistency is a top priority.

RoHS in the Context of High-Reliability Electronics

High-reliability applications require electronics to operate in challenging environments over long service lives. In these sectors, RoHS conformity must be achieved without compromising performance, durability, or safety.

The restriction on lead content in solder alloys is a notable example. Lead-free solders typically have higher melting points and different mechanical properties compared to traditional tin-lead alloys. This change can alter how assemblies handle thermal stress and mechanical fatigue.

For industries such as aerospace, defense, and medical devices, these differences influence thermal management, solder joint integrity, and inspection criteria. Manufacturers serving these markets adopt specialized alloys, refined soldering profiles, and targeted inspection methods to maintain reliability while meeting RoHS standards.

Technical Implications of RoHS for PCB Assemblies

RoHS compliance impacts material selection, soldering processes, and inspection requirements for PCB assemblies. The elimination of lead in solder changes the thermal characteristics of the joint, often requiring higher reflow temperatures. This can place additional stress on components, laminate materials, and surface finishes.

Lead-free solders may also exhibit different wetting behavior, affecting joint geometry and potentially influencing long-term reliability. Component terminations, solder masks, and plating finishes must be compatible with lead-free processing to avoid defects.

For high-reliability applications, these factors drive the need for controlled reflow profiles, rigorous quality checks, and the use of materials tested for stability under elevated temperatures and extended service conditions.

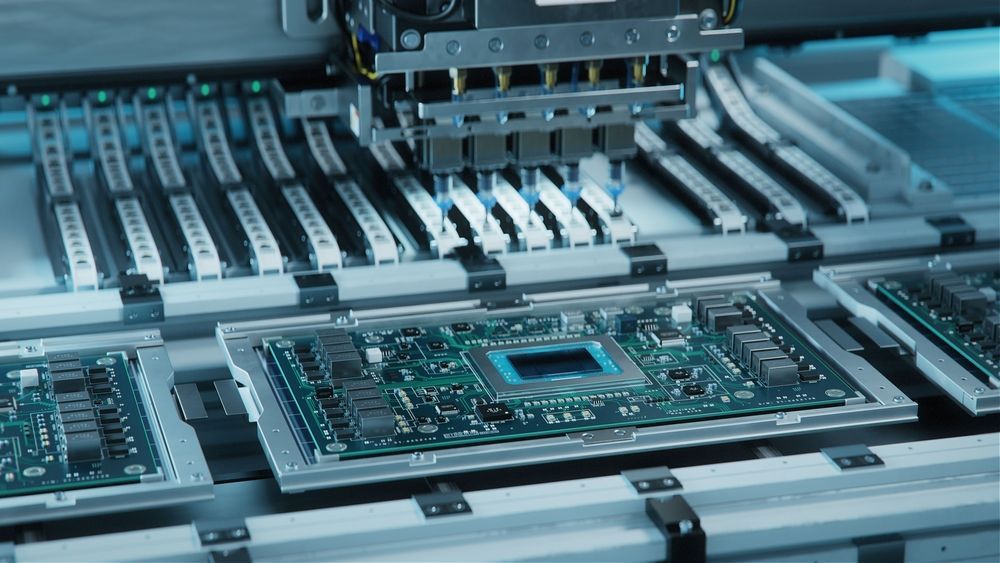

Process Controls for RoHS-Compliant PCB Assembly

Achieving RoHS-compliant PCB production requires process control at every stage. Material verification is the first step, confirming that all components and consumables meet restricted substance limits. Incoming parts are often validated through supplier certifications and random analytical testing.

Assembly processes must be tuned for lead-free solders, including optimized reflow profiles, compatible flux chemistries, and controlled cooling rates to maintain joint integrity. Equipment calibration and maintenance schedules are critical to prevent cross-contamination from non-compliant materials.

In high-reliability builds, inspection checkpoints are integrated throughout production. Automated optical inspection, X-ray analysis, and targeted functional tests confirm both compliance and performance before assemblies move to the next stage.

Documentation, Traceability, and Supply Chain Compliance

Maintaining RoHS alignment depends on accurate documentation and supply chain coordination. Manufacturers must collect and store declarations of conformity from component suppliers, confirming that materials meet the directive’s limits on restricted substances. These records support audits and customer requirements.

Traceability links each assembly to its materials, lot codes, and process history. This allows any compliance concern to be isolated quickly without impacting unrelated production.

Supply chain management is equally important. Approved vendor lists, periodic supplier evaluations, and contract requirements help prevent non-compliant materials from entering production. In high-reliability sectors, documentation and traceability form part of the quality record for every shipped assembly.

Lifecycle and Obsolescence Risk Under RoHS

RoHS rules can influence the availability of components over time. When manufacturers discontinue non-compliant parts, sourcing alternatives becomes necessary to keep production running. In some cases, form-fit-function replacements are available, but performance characteristics or reliability ratings may differ.

Long-lifecycle products in aerospace, defense, or medical sectors face greater exposure to obsolescence risk. Planning for compliance involves proactive component selection, supplier coordination, and maintaining strategic inventory levels.

Lifecycle management also benefits from ongoing monitoring of supplier announcements and regulatory updates. These steps reduce the likelihood of redesigns late in the product’s life, helping maintain both compliance and uninterrupted delivery to customers.

RoHS and Regulatory Crossovers

RoHS compliance often intersects with other environmental and safety regulations. For example, the Waste Electrical and Electronic Equipment (WEEE) directive focuses on recycling and responsible disposal of electronics, complementing RoHS objectives. In some markets, REACH regulations address additional hazardous substances not covered under RoHS, requiring broader material disclosure.

In the United States, industry-specific requirements may add further complexity, particularly for defense and medical applications. Understanding how RoHS aligns with or differs from these regulations helps manufacturers maintain compliance across all applicable frameworks. Coordinated compliance strategies reduce duplication of effort, simplify audits, and strengthen confidence in both the manufacturing process and the finished product.

EI Microcircuits' Approach to RoHS in High-Reliability PCBA

EI Microcircuits incorporates RoHS compliance into every stage of high-reliability PCB assembly. Material selection begins with sourcing components from approved vendors that provide complete compliance documentation. Incoming parts are validated through both supplier records and in-house testing when required.

Production processes are configured for lead-free soldering, controlled reflow profiles, and contamination prevention. Inspection checkpoints, including X-ray and automated optical inspection, confirm both performance and material compliance.

The company’s quality management systems, including ISO 13485 and AS9100D, provide the structure for traceability, supplier control, and continuous improvement. This integrated approach supports OEM customers in meeting environmental regulations while maintaining the performance and reliability their products demand.

Key Takeaways

RoHS compliance shapes how high-reliability PCB assemblies are designed, sourced, and manufactured. It influences material selection, soldering processes, documentation practices, and supply chain controls. Meeting these requirements protects the environment, supports market access, and reinforces product quality.

For OEMs in sectors such as aerospace, defense, and medical devices, compliance must be achieved without compromising performance or service life. Partnering with a manufacturer experienced in both RoHS requirements and high-reliability production streamlines this process and reduces risk.

Contact EI Microcircuits today to discuss how our RoHS-compliant manufacturing

capabilities can support your next

project.

let's talk

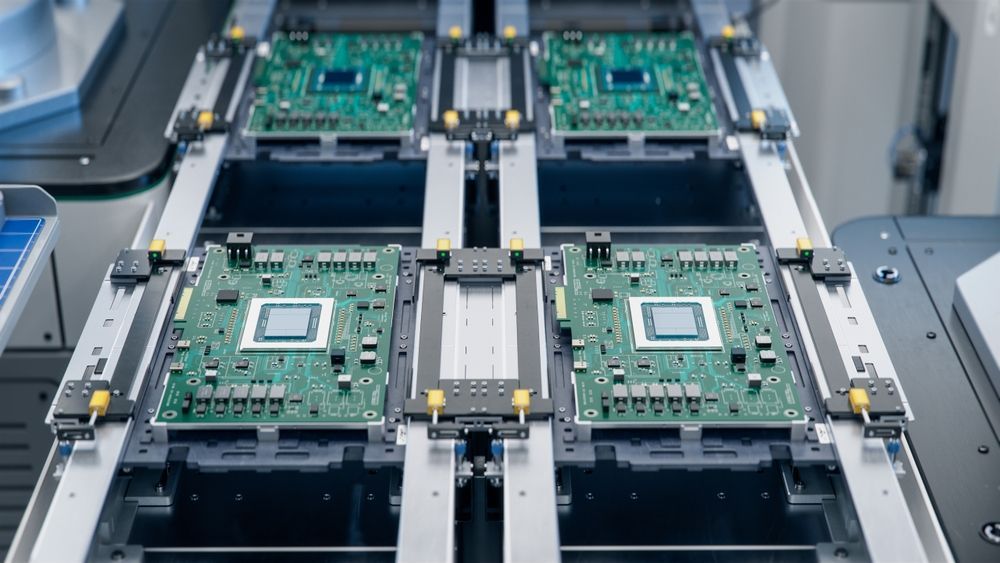

EI Microcircuits is comprised of three production facilities totaling over 100,000 square feet of climate-controlled manufacturing, engineering and warehousing. We are ready to be the solution to your next project. Contact Us, Request a Quote or Schedule a Tour today!

Manufacturing plant 1

1651 Pohl Road

Mankato, MN 56001

P: 507.345.5786

Manufacturing plant 2

2011 Klein Street

St. Peter, MN 56082

P: 507.934.5722

manufacturing plant 3

69 Power Drive

Mankato, MN 56001

P: 507.386.9160

*Each facility is configured to support your production needs. While maintaining continuity with each other in equipment, training and process control, each facility offers its own specialty. All facilities share the same data center to allow for seamless manufacturing between locations.