Understanding Surface Mount Technology (SMT)

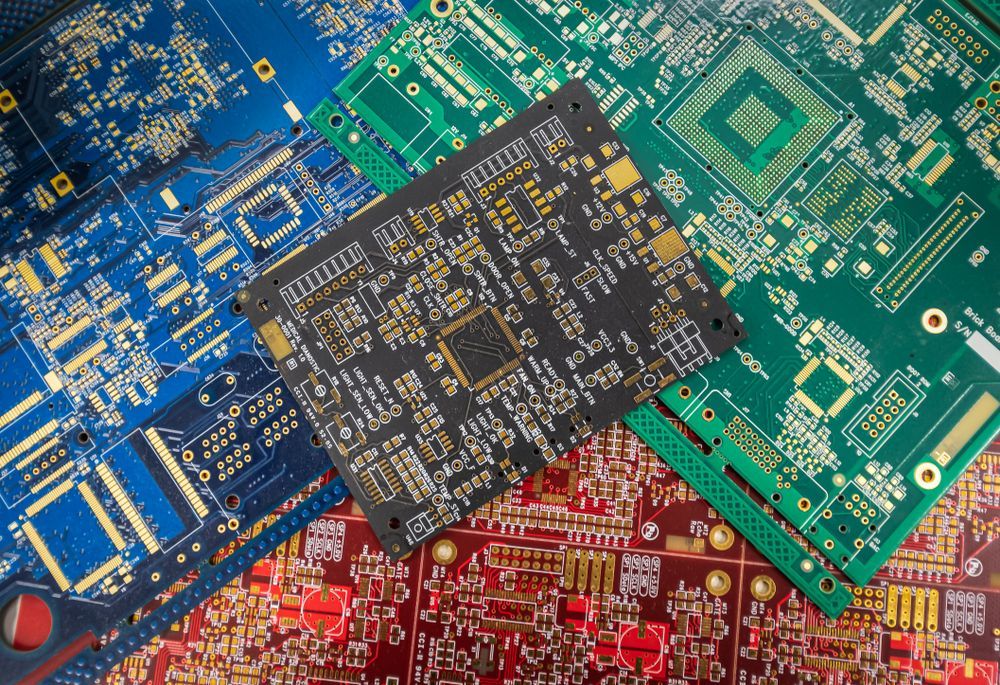

Surface Mount Technology (SMT) is a core method used in the assembly of modern electronic devices. It enables components to be mounted directly onto the surface of a printed circuit board, allowing for tighter layouts, higher performance, and automated assembly.

This approach supports the growing need for miniaturization and precision across sectors such as medical, aerospace, defense, and industrial automation. SMT also streamlines production workflows and improves reliability in high-mix, low to medium volume builds.

EI Microcircuits uses equipment to automate the placement and inspection of surface mount components so our customers receive a high-quality product. EI Microcircuits equipment is advanced and can accurately place the smallest surface mount components on the planet.

What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) refers to a method of assembling electronic circuits where components are placed directly onto the surface of a printed circuit board (PCB). Unlike through-hole technology, SMT does not require leads to pass through the board. Instead, it uses solder paste and reflow soldering to create secure electrical and mechanical connections.

This technique allows for smaller, lighter components and more efficient use of board space. SMT is compatible with high-speed automation, making it ideal for complex, high-density assemblies. It supports advanced functionality in compact designs and is widely used across medical, aerospace, and industrial applications.

Advantages of Surface Mount Technology

Surface Mount Technology offers significant advantages in performance, efficiency, and design flexibility. Components are typically smaller and lighter, enabling more compact assemblies and higher circuit density. This results in faster signal transmission, reduced inductance, and better thermal performance.

SMT also supports automated placement and reflow soldering, improving throughput and repeatability while reducing labor variability. It also simplifies double-sided board design and reduces drilling requirements.

For OEMs in regulated sectors, SMT helps meet strict quality and traceability standards. Its compatibility with high-mix production makes it well-suited for assemblies that demand reliability, precision, and consistency across varying batch sizes.

Challenges in SMT

Despite its advantages, SMT presents several engineering and process challenges. Component miniaturization increases the risk of placement errors and solder joint defects, especially in fine-pitch packages like BGAs and QFNs. Mixed technologies of surface mount and through hole components present challenges in soldering and thermal profiling the board for production.

Thermal management also becomes more complex as power densities increase. Moisture sensitivity, warping during reflow, and tombstoning in passive parts can compromise yield. SMT also requires tight process control and continuous inspection to maintain quality across production runs.

For OEMs working in regulated industries, these risks must be managed through robust design validation, material selection, and traceable process control. Partnering with a skilled contract manufacturer helps mitigate these production variables.

The SMT Manufacturing Process

The SMT manufacturing process begins with solder paste application using a precision stencil printer to deposit material onto each pad. High-speed pick-and-place machines then position components based on CAD data.

Assemblies pass through a reflow oven, where controlled heat profiles melt the solder and form mechanical and electrical connections. Post-reflow, boards undergo inspection using Automated Optical Inspection (AOI) and, when necessary, X-ray imaging to verify hidden joints.

For complex builds, additional steps like selective soldering, conformal coating, or flying probe testing may follow. Every stage must be tightly controlled to maintain consistency, especially in mission-critical and regulated environments.

Applications of Surface Mount Technology

Surface Mount Technology supports a wide range of high-reliability applications across demanding sectors:

- Medical Devices: Implantables, diagnostic equipment, and patient monitoring systems

- Aerospace and Defense: Avionics, control systems, secure communications, and unmanned platforms

- Industrial Automation: Motor drives, embedded controllers, power modules, and smart sensors

- Telecommunications: Network infrastructure, signal processors, and fiber-optic modules

- Automotive Systems: ECU modules, ADAS platforms, and powertrain electronics

- Consumer and IoT Devices: Wearables, smart home controllers, and portable electronics

Design for Manufacturability (DFM) in SMT

Design for Manufacturability in SMT focuses on creating layouts and specifications that support efficient, repeatable, and high-quality assembly. This includes clear component spacing, standardized footprints, and appropriate solder mask clearance to reduce bridging or tombstoning.

Pad designs must also match part geometry to prevent misalignment during placement and reflow. DFM also considers thermal relief, panelization, and stencil aperture optimization to support uniform solder deposition.

Early collaboration between design engineers and manufacturing teams helps identify risks before production. At EI Microcircuits, we integrate DFM feedback into each project to improve yield, reduce rework, and accelerate time to market.

SMT Testing and Quality Control

Testing and quality control are integral to reliable SMT assembly. At EI Microcircuits, each build begins with in-process inspection using Automated Optical Inspection (AOI) to catch placement and solder defects.

For components like BGAs or QFNs, X-ray imaging confirms internal connections. Electrical testing follows, using in-circuit testing (ICT), flying probe, or full functional verification to validate performance against specifications.

Lastly, traceability is maintained through serialized labeling and lot tracking. For regulated sectors, documentation and test records must align with industry standards such as IPC-A-610, ISO 13485, or AS9100D.

Choosing the Right SMT Partner

Selecting the right SMT partner involves more than evaluating capabilities. Look for experience in your industry and evidence of compliance with relevant quality management systems such as ISO 13485 or AS9100D. Assess their ability to handle complex builds, adapt to schedule changes, and support high-mix, low to medium volume production. Strong partners offer design support, testing options, and transparent communication throughout the project lifecycle as well.

Be sure to review their process controls, inspection systems, and track record for on-time delivery. At EI Microcircuits, we work as an extension of your manufacturing, combining precision, flexibility, and long-term support to meet your product and quality goals.

Get Started with EI Microcircuits

At EI Microcircuits, we specialize in building high-reliability SMT assemblies for OEMs in medical, aerospace, defense, and industrial markets. Our team supports projects from initial design review through final test and logistics, all under one roof.

We offer surface mount and through-hole assembly, box-build integration, conformal coating, overmolding, and comprehensive testing services. Customers count on us for flexibility, responsiveness, and consistent quality across every build.

If you're seeking a manufacturing partner that understands precision requirements and regulatory expectations, we're ready to collaborate. Contact us today to find a solution to your electronics manufacturing challenges.

let's talk

EI Microcircuits is comprised of three production facilities totaling over 100,000 square feet of climate-controlled manufacturing, engineering and warehousing. We are ready to be the solution to your next project. Contact Us, Request a Quote or Schedule a Tour today!

Manufacturing plant 1

1651 Pohl Road

Mankato, MN 56001

P: 507.345.5786

Manufacturing plant 2

2011 Klein Street

St. Peter, MN 56082

P: 507.934.5722

manufacturing plant 3

69 Power Drive

Mankato, MN 56001

P: 507.386.9160

*Each facility is configured to support your production needs. While maintaining continuity with each other in equipment, training and process control, each facility offers its own specialty. All facilities share the same data center to allow for seamless manufacturing between locations.