Exploring the Costs of Custom PCBs and PCBA

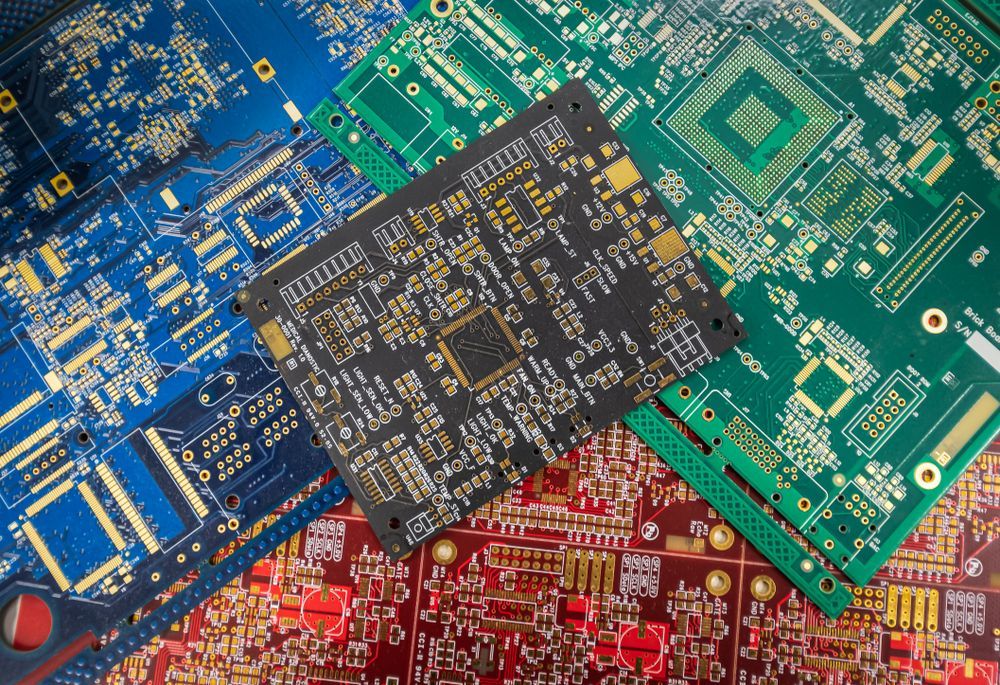

Custom printed circuit boards (PCBs) and printed circuit board assembly (PCBA’s) are central to innovation in medical devices, aerospace systems, defense electronics, and industrial electronics. But with performance requirements comes complexity and cost. Understanding what drives cost in a custom PCB/PCBA program enables better decision-making, fewer surprises, and more reliable long-term performance.

This guide outlines the technical and operational cost factors of custom PCBs and PCBA’s. It also describes how EI Microcircuits supports customers through precision manufacturing, integrated services, and lifecycle cost control.

What Drives costs in a custom PCB.

A PCB’s cost rises when it departs from standard configurations in form, function, or materials. High-reliability applications often require custom PCBs to meet electrical performance, thermal management, or regulatory criteria. Common custom attributes include:

- Non-standard layer counts or high-density interconnects (HDI)

- Specialty materials such as high-Tg laminates or RF substrates

- Controlled impedance and complex routing requirements

- Unique board outlines or mechanical features

- Blind or buried vias, via-in-pad, or embedded components

- Regulatory documentation for FDA, ITAR, or aerospace compliance

- Rapid production turn time will drive up the cost regardless of complexity.

Core Cost Drivers in Custom PCB Design

Design phase activities influence both direct and indirect cost. Key drivers include:

- Engineering labor for schematic capture and PCB layout

- Time spent on signal integrity, impedance control, and power distribution

- DFM and DFT reviews that reduce downstream issues

- Material stack-up selection based on electrical and thermal requirements

- Documentation development for traceability and compliance

Early investment in DFM is critical. It reduces rework, supports testability, and ensures manufacturability at scale. At EI Microcircuits, we embed DFM support into the new product introduction (NPI) process to control cost and maintain yield from prototype to production.

PCB Manufacturing Cost Factors

PCB fabrication introduces cost based on board complexity and process control requirements. Primary contributors include:

- Layer count and dimensions, which affect panel utilization and lamination cycles

- Drill types and densities, including laser microvias or mechanically drilled blind vias

- Surface finishes such as ENIG, immersion silver, or OSP

- Tolerance requirements for trace widths, hole sizes, and impedance

- Quality assurance processes required to meet IPC Class 2 or Class 3 standards

- Foreign or Domestic Production location greatly impacts PCB board cost especially with lower layer counts.

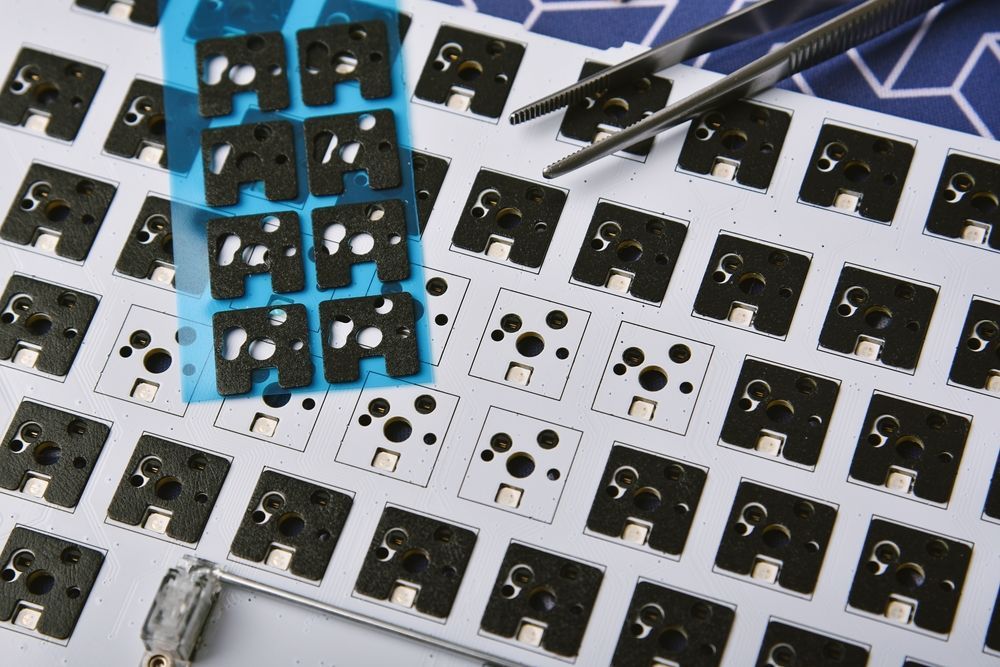

PCB Assembly Cost Considerations

Assembly costs for custom PCBs vary with part count, process complexity, and inspection criteria. Key cost elements include:

- Component sourcing, especially for long-lead, high-reliability, or specialized parts

- SMT and through-hole process complexity, including fine-pitch BGAs and high-density layouts

- Conformal coating, selective soldering, or overmolding as part of environmental protection

- Inline inspection such as AOI, X-ray, and ICT to verify placement, solder joint quality, and electrical performance

- Labor for manual assembly, troubleshooting, or rework during early production phases

Testing is often the most overlooked cost area. Functional test development, fixture fabrication, and validation protocols all require planning and documentation. We integrate functional testing and in-circuit test options as part of our turnkey manufacturing system.

Volume, Lead Time, and Cost Trade-Offs

Build volume and schedule affect unit cost and overall program economics. Consider the following trade-offs:

- Early builds, such as prototypes or validation units, carry high setup costs and low yield. They are critical for design but not cost-optimized.

- Production volumes benefit from economies of scale, better panel optimization, and improved process yield.

- Compressed lead times increase cost due to expedited material handling, overtime labor, and constrained test capacity.

At EI Microcircuits, we support

scalable builds with the same engineering rigor and documentation standards. Our systems are designed to support low-to-medium volume, high-mix programs without compromising quality or traceability.

Hidden and Lifecycle Costs

The full cost of a custom PCB program includes more than materials and labor. Program leads must also account for:

- Engineering spin cycles caused by inadequate DFM or test planning

- Supplier management complexity from disaggregated build partners

- Regulatory risk due to incomplete documentation or process validation

- Field failure risk and warranty claims due to undetected manufacturing defects

- Configuration control and revision tracking across the product lifecycle

Lifecycle cost can often exceed the initial build cost. Designs that are difficult to test, source, or rework introduce long-term risk. Our integrated approach mitigates these issues with traceability systems, documentation control, and proactive supply chain management.

EI Microcircuits’ Approach to Cost-Efficient US PCBA

We approach cost control from a systems perspective. Our processes are structured to reduce failure modes, increase first-pass yield, and optimize total cost of ownership. Key elements include:

- A closed-loop NPI process that incorporates DFM and process simulation

- Vertically integrated services including PCB assembly, conformal coating, overmolding, and full box-builds

- Embedded inspection and testing, including AOI, X-ray, flying probe, ICT, and functional validation

- Controlled environments and static protection per ANSI/ESD S20.20

- Quality management systems including ISO 13485 and AS9100D

- ITAR-registered facility with documented control processes for export-regulated products

- Copy-Exact production facilities for disaster mitigation

This integrated approach reduces supplier handoffs, eliminates documentation gaps, and maintains consistent quality across build phases. We serve as an extension of our customers’ manufacturing systems, delivering flexibility without compromising compliance.

Key Takeaways

- Custom PCBs are defined by non-standard features, materials, or compliance requirements. These introduce both direct and indirect cost.

- Cost drivers span engineering design, board fabrication, assembly, test, and lifecycle maintenance.

- Hidden costs from poor DFM, fragmented supply chains, or rework can exceed initial estimates.

- Volume and lead time influence cost but must be balanced against program maturity and compliance demands.

- EI Microcircuits offers a cost-controlled, integrated solution that aligns with mission-critical build requirements across regulated industries.

Contact us today to discuss your custom PCB program and how we can help reduce cost, lead time, and risk.

let's talk

EI Microcircuits is comprised of three production facilities totaling over 100,000 square feet of climate-controlled manufacturing, engineering and warehousing. We are ready to be the solution to your next project. Contact Us, Request a Quote or Schedule a Tour today!

Manufacturing plant 1

1651 Pohl Road

Mankato, MN 56001

P: 507.345.5786

Manufacturing plant 2

2011 Klein Street

St. Peter, MN 56082

P: 507.934.5722

manufacturing plant 3

69 Power Drive

Mankato, MN 56001

P: 507.386.9160

*Each facility is configured to support your production needs. While maintaining continuity with each other in equipment, training and process control, each facility offers its own specialty. All facilities share the same data center to allow for seamless manufacturing between locations.