More than Just PCB Assembly

Of all PCB manufacturing companies, EI Microcircuits takes pride in building high-quality products that surpass industry standards. But did you know? We don’t just assemble circuit boards. From testing to conformal coating to box builds and more, we offer a variety of value added services to customers in different industries. Read on to learn about these services and see how you can utilize them for your next project.

Supreme Testing

With a 0.4% return rate over the last 12 months, we have the stats to prove that we’re dedicated to making sure our PCB products are in pristine condition when we finish them. Through every stage of the production process, we make sure that each board is thoroughly tested multiple times. From the very start of the assembly process we use the latest technology in our SMT lines, like our 3D SPI, 3D AOI and X-Ray machine to test each board for correct placement of components, polarity, insufficient solder and more. Then, towards the end of the process, we offer the Flying Probe test to ensure that the product will function properly.

Exceptional Protection

Some of our customer’s applications require more protection, which is why we offer conformal coating as well as Overmolding and potting.

Conformal coating is applied to protect against the elements such as moisture, dust and chemicals that could result in damage. Potting offers the same benefits, but completely encloses the PCB to allow further benefits such as resistance to shock, vibration and extreme elements. For both of these services, we have the dedicated space, machines, and trained operators to ensure correct application and quality.

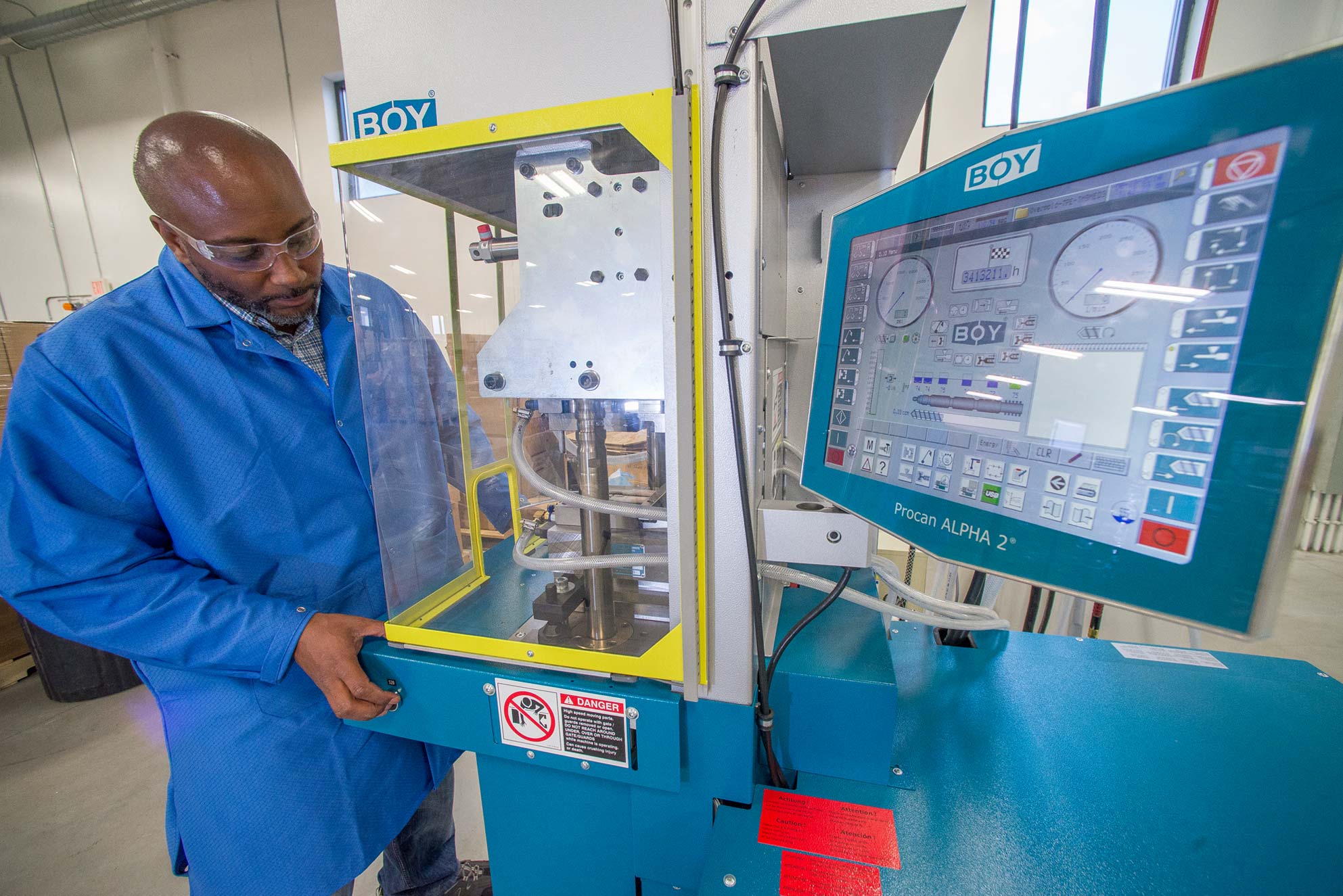

We offer our customers the option to utilize our 25 ton BOY vertical injection molding machine which offers many advantages. These advantages include a durable finished product, aesthetically pleasing with color and logo options as well as enhanced safety features.

Full Box Build Assembly

An additional service we offer to our customers is the assembly of the complete box build enclosure. We have a dedicated facility for this process and offer a wide variety of options to meet your product needs. From full electromechanical assembly, installation of sub-assemblies and components, installation, routing of cables and wire harnesses, and final product packaging, we’re committed to making sure each product is assembled correctly.

Exceeding Expectations

From agriculture electronics to military engineering to medical electronics and more, we’re dedicated to being a leader in the industry as a value added service provider. Our vast knowledge and experience allows us to offer these additional services, and we look forward to continuing to exceed expectations in the electronics industry.

Ready to take advantage of these value added services for your project? Get in touch with us! We’d be happy to discuss how we can create the product you’re looking for.